What is a conventional air spray gun?

A conventional air spray gun is a system powered by regular or, in some cases, specialized air compressors. They are used for applying paint and other coatings to a variety of surfaces, such as cars, furniture, and walls.

A conventional air spray gun is a system powered by regular or, in some cases, specialized air compressors. They are used for applying paint and other coatings to a variety of surfaces, such as cars, furniture, and walls.

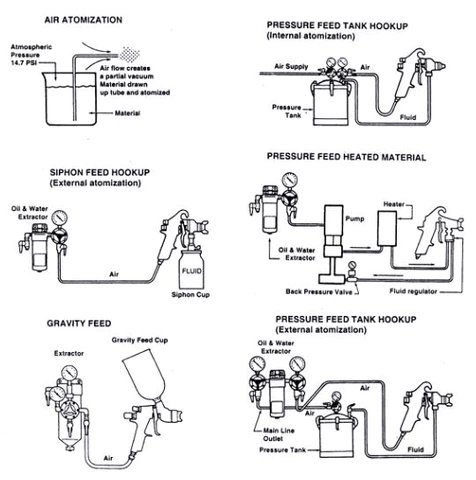

It operates by drawing the material (paint) from a container, such as a paint cup, and then atomizing the material by forcing it through a nozzle with the help of compressed air.

The conventional air spray gun uses a high-pressure air stream to break up the sprayed material, creating a fine mist evenly distributed over the surface being painted. The air and material are mixed inside the gun and then expelled through the nozzle.

Table of Contents

- When and why was the air spray gun with compressor invented?

- Two primary components of conventional air spray mechanism

- What kind of paints can be used with them?

- What are their applications?

- What is a conventional air sprayer for heated material?

- What are the advantages and disadvantages?

- Frequently asked questions

- Conclusion

When and why was the air spray gun with compressor invented?

Invented – late 19th century – The first air spray gun was invented in the late 19th century by an American inventor named Francis H. Spray. However, in the early 20th century, air spray guns became widely used in industrial applications, particularly in the automotive industry.

For faster, more efficient application – Using air spray guns with compressors allowed for faster, more efficient application of paint and other coatings. Before the invention of the air spray gun, paints, and coatings were often applied using brushes, rollers, or other manual methods, which were time-consuming and labor-intensive.

Allows the use of higher-viscosity materials – The use of compressed air allowed for a more uniform and controlled spray pattern, which resulted in a more even and consistent coating. Also, air spray guns allowed for the use of higher-viscosity materials, such as enamels and lacquers, which were difficult to apply with manual methods.

Two primary components of conventional air spray mechanism

There are two primary components in a conventional air spray gun setup, which include the two components: the spray gun itself and the air compressor.

(1) The air compressor:

The air compressor is a separate piece of equipment that provides the compressed air necessary for atomizing the material and propelling it out of the spray gun. The compressor must be capable of delivering a consistent, clean supply of air at the correct pressure and volume to achieve the desired finish. The type and size of compressor needed will depend on the specific application, and the size and complexity of the spray gun used.

Can I use any spray gun with an air compressor?

No, you cannot use any spray gun with an air compressor. Air spray guns with compressors are designed to work with specific types of spray guns, which are often referred to as conventional or air-atomizing spray guns.

Conventional spray guns are designed to use compressed air to atomize the paint or coating and create a fine mist, which is then applied to the surface being painted. They typically have a metal fluid nozzle and a needle regulating the paint or coating flow.

Other types of spray guns, such as airless and HVLP (high-volume, low-pressure) spray guns, do not require a compressor and operate on different principles. These spray guns are not compatible with air compressors and cannot be used with them.

It’s important to choose the correct spray gun for your application and ensure that it is compatible with your air compressor before attempting to use it.

(2) The spray gun body:

The spray gun body is the main housing that contains the fluid nozzle/needle and air cap. It typically has a trigger that controls air and material flow, allowing the operator to start and stop the spray as needed. The body may also have adjustment knobs or controls to regulate the spray pattern, fan width, and material flow rate.

Two primary components of a conventional air spray gun mechanism

Fluid nozzle and needle

The fluid nozzle and needle control the flow of the material being sprayed. The fluid nozzle is a small, circular opening at the end of the spray gun that allows the material to be sprayed out, while the needle is a thin, pointed rod that fits inside the fluid nozzle and controls the size of the opening. By adjusting the needle position, the operator can control the flow rate of the material being sprayed.

Air cap

The air cap is a component located at the front of the spray gun that controls the spray pattern and the atomization of the material being sprayed. The air cap has a series of holes or slots that direct the compressed air over the fluid nozzle and needle, creating a low-pressure area that atomizes the material and distributes it evenly over the surface being painted. The air cap also helps to shape the spray pattern, which can be adjusted by changing the air cap orifice size or pattern adjustment knob.

What kind of paints can be used with them?

Air spray guns with compressors can be used with a wide range of paints and coatings, including:

- Solvent-based paints: These paints use solvents such as mineral spirits, acetone, or toluene to dissolve the pigments and binders. They are commonly used in automotive, industrial, and marine applications, providing excellent durability, adhesion, and resistance to chemicals and weathering.

- Water-based paints: These paints use water as the primary solvent rather than traditional solvents. They are often used in residential and commercial applications, emitting fewer fumes and having lower VOC (volatile organic compound) emissions than solvent-based paints. Water-based paints also tend to dry more quickly, which can be advantageous in certain applications.

- Oil-based paints: These are paints that use linseed oil or other vegetable-based oils as the primary solvent. They are often used in interior and exterior painting applications, providing excellent durability, flow, and leveling. However, they emit more fumes than water-based paints and require solvents such as turpentine or mineral spirits for cleanup.

- Lacquers: These coatings use a solvent-based system to dissolve the pigments and binders. They are commonly used in wood finishing and automotive applications, providing a high-gloss finish and excellent durability.

- Stains: These are coatings designed to penetrate the surface of wood rather than forming a film on top. They are often used in furniture, cabinetry, and flooring applications, as they enhance the natural beauty of the wood while providing protection against wear and tear.

It’s important to note that not all paints and coatings are suitable for air spray guns with compressors. It’s always best to consult the manufacturer’s recommendations and follow proper safety procedures when working with these materials.

What are their applications?

Air spray guns with compressors have a wide range of applications in various industries. Here are some of the typical applications:

Automotive

Air spray guns are widely used in the automotive industry to paint cars, trucks, and other vehicles. They are used to apply primers, basecoats, clearcoats, and other coatings.

Woodworking

Air spray guns are used in woodworking to apply stains, varnishes, and other finishes to furniture, cabinets, and other wood products. They are also used to apply paint and other coatings to wooden surfaces.

Aerospace

Air spray guns are used in the aerospace industry to apply coatings to aircraft components, including fuselages, wings, and engines. They are used to apply protective coatings as well as to provide a decorative finish.

Industrial

Air spray guns are used in many industrial applications, including coating metal parts, appliances, and machinery. They are used to apply protective coatings, such as rust inhibitors, and to provide a decorative finish.

Construction

Air spray guns are used in construction for painting walls, ceilings, and other surfaces. They are used to apply primers, paints, and other coatings and can provide a faster and more efficient application method than traditional brush or roller methods.

Marine

Air spray guns are used in the marine industry to apply coatings to boats, ships, and other watercraft. They are used to apply protective coatings as well as to provide a decorative finish.

Arts and crafts

Air spray guns are also used in the arts and crafts industry to apply paint, glaze, and other coatings to ceramics, pottery, and other surfaces.

Overall, air spray guns with compressors are versatile and efficient tools for applying coatings to a wide range of surfaces and materials.

What is a conventional air sprayer for heated material?

Image source: finishsystems

A conventional air sprayer for heated material, also known as a hot spray system, is a type of spray gun designed to handle and apply high-viscosity coatings that require heating to reduce their thickness and make them easier to spray. This type of spray gun is commonly used to apply materials like adhesives, mastics, sealants, and other coatings that are too thick to apply with a standard air spray gun.

Hot spray systems typically use a separate heating unit connected to the spray gun via heated hoses. The heating unit warms the material to the desired temperature and reduces its viscosity, making it easier to spray. The heated material is then delivered to the spray gun through the heated hoses, where it is atomized with compressed air and applied to the surface being coated.

Hot spray systems are often used in industrial and commercial applications where high-viscosity coatings must be applied quickly and efficiently. They offer several advantages over traditional air spray guns, including improved flow and atomization, reduced waste, and increased productivity. However, they also require specialized equipment and training to operate effectively, and they may only be suitable for some types of coatings or surfaces.

What are the advantages and disadvantages?

Advantages:

- High-quality finish: Air spray guns can produce a high-quality, even finish with a smooth texture and consistent coverage.

- Versatility: They can be used to apply a wide range of materials, including paints, lacquers, stains, varnishes, and more.

- Efficiency: Air spray guns can cover large areas quickly and evenly, resulting in faster completion times and reduced labor costs.

- Control: They provide precise control over the spray pattern, fan width, and material flow, allowing the operator to adjust the settings for specific applications.

- Adaptability: Air spray guns can be used with a range of nozzle sizes and air pressure settings, making them adaptable to different materials and projects.

Disadvantages:

- Overspray: Air spray guns can generate overspray, which is wasted material that does not adhere to the surface being coated. This can result in material waste and additional cleanup time.

- Health risks: Using air spray guns with some materials can generate airborne particles and fumes that can harm the operator’s health if inhaled. Appropriate safety precautions, such as respirators and protective clothing, should be taken when using air spray guns.

- Noise: Air compressors can generate noise levels that may be disruptive to others in the vicinity and require additional sound-dampening measures to reduce noise pollution.

- Maintenance: Air spray guns require regular cleaning and maintenance to ensure consistent performance and prevent clogging or other issues.

- Cost: Air spray guns with compressors can be relatively expensive compared to other painting methods and may require additional investment in equipment and training for operators.

Frequently asked questions

What is the difference between a conventional air spray gun and an HVLP spray gun?

Answer

Conventional air spray guns use compressed air to atomize the paint or coating, while HVLP (high-volume, low-pressure) spray guns use a high volume of air at a low pressure to atomize the paint or coating. HVLP spray guns are generally more efficient and produce less overspray, but they may only be suitable for some applications.

What kind of maintenance do air compressors require?

Answer

Air compressors require regular maintenance, such as changing the oil, cleaning or replacing air filters, and inspecting and tightening belts and fittings. It is important to follow the manufacturer’s recommendations for maintenance and to perform any necessary repairs or replacements as soon as possible to ensure the safe and efficient operation of the compressor.

Can any paint be used with an air spray gun?

Answer

Not all types of paint are suitable for use with air spray guns. It is important to choose a paint compatible with the type of air spray gun and compressor being used, as well as the surface being painted. The manufacturer’s recommendations should always be followed to ensure proper performance and safety.

What are some safety precautions when using air spray guns and compressors?

Answer

When working with air spray guns and compressors, it is important to wear appropriate personal protective equipment (PPE), such as goggles, gloves, and a respirator. Always follow the manufacturer’s recommendations and proper procedures for use, and be aware of any hazards associated with the tool or equipment being used. It is also important to follow proper electrical and grounding procedures to prevent static electricity buildup and the risk of fires or explosions.

Conclusion

Air spray guns and compressors are powerful tools commonly used in various industrial, commercial, and residential applications. These tools are often used together to quickly and efficiently apply paint and other coatings to various surfaces quickly and efficiently.

Air compressors convert power into compressed air, which is then used to power air spray guns and other pneumatic tools.

Air spray guns are designed to use compressed air to atomize paint and coatings, creating a fine mist that is then applied to the surface being painted.

These versatile and efficient tools require proper maintenance and safety precautions to ensure their safe and effective use.